The new rammed earth, slimmed down and ready for the show, complements the palette of crisp, modern finishes in the lobby of the six-story Stadium TechCenter in Santa Clara, California. Interior design by SmithGroupJJR.

For thousands of years, rammed earth has been a hallmark of sustainable construction - thick insulating walls made from rock and earth sourced from the building site itself, or just nearby. Rammed earth has gone through a renaissance of sorts over the past 30 years with the craft being celebrated and appreciated by modern architects. But beyond refining the technique and making it conform to modern building codes, not a lot has changed - rammed earth walls are typically thick, insulating, load bearing and exterior.

Now, interior designers and architects are looking for the beauty of rammed earth without the bulk. How can rammed earth continue to modernize in the face of ever evolving construction techniques? Big buildings are made of glass and steel, insulation standards have mandated a certain type of interior-exterior separation, and more important than anything, cost and speed of construction are relegating traditional rammed earth back into the past. But what if there were a different way of adapting rammed earth to our modern era?

I remember the first meeting with the architects at the SmithGroupJJR in San Francisco. I was there with Khyber, our most experienced rammed earth installer, and Dan, our project coordinator. SmithGroup had been awarded the contract to design the lobby for the new Stadium TechCenter in Santa Clara, and they wanted to push the envelope with an exciting, sustainable, new design concept. How much further could you push interior design than hanging a 30,000 pound mural made of compacted earth on the wall behind the reception desk? Dan, Khyber, and I stole glances at each other, knowing that if I said “yes” we were committing ourselves to something that had never been done before.

Depending on the epoch and the thousand year floods, nature can lithify layers of sedimentary rock that are deep and highly contrasting, or pencil thin. It can take a million years to build a rock five feet thick.

Our last project that called for a lobby feature wall - the American AgCredit building - was designed around a more traditional, thick monolithic rammed earth wall. The construction process gave us some limited room to build the interior wall while the rest of the building’s steel structure was assembled around it. But in this case, the Stadium TechCenter already had the steel superstructure and intermediate floors in place. There was no way the owner was going to let us bring formwork into the lobby and make all the mess and noise associated with classic cast in place rammed earth, not to mention how much this would disrupt the schedule. No, we’d have to figure out a way to make the wall off site and transport it to Santa Clara. Simply put, we’d have to bring the mountain to Mohammed.

How could we manufacture long pieces of rammed earth thin and light enough to transport, yet strong and stiff enough to survive the bumps along the road? Could we engineer an assembly to mount thin wall panels two stories high onto a structural back wall, and would they stay there in a big California earthquake?

What was the biggest challenge? Making a relatively thin rammed earth wall at our shop? No, we’ve been building thin mock-ups for years as samples. Picking the wall up and loading it on a truck? No, we’ve delivered mock-ups to clients multiple times. Making a wall out of many different layers and colors? No, we’d just done this for American AgCredit. The challenge here was the scale and the complexity of the operation.

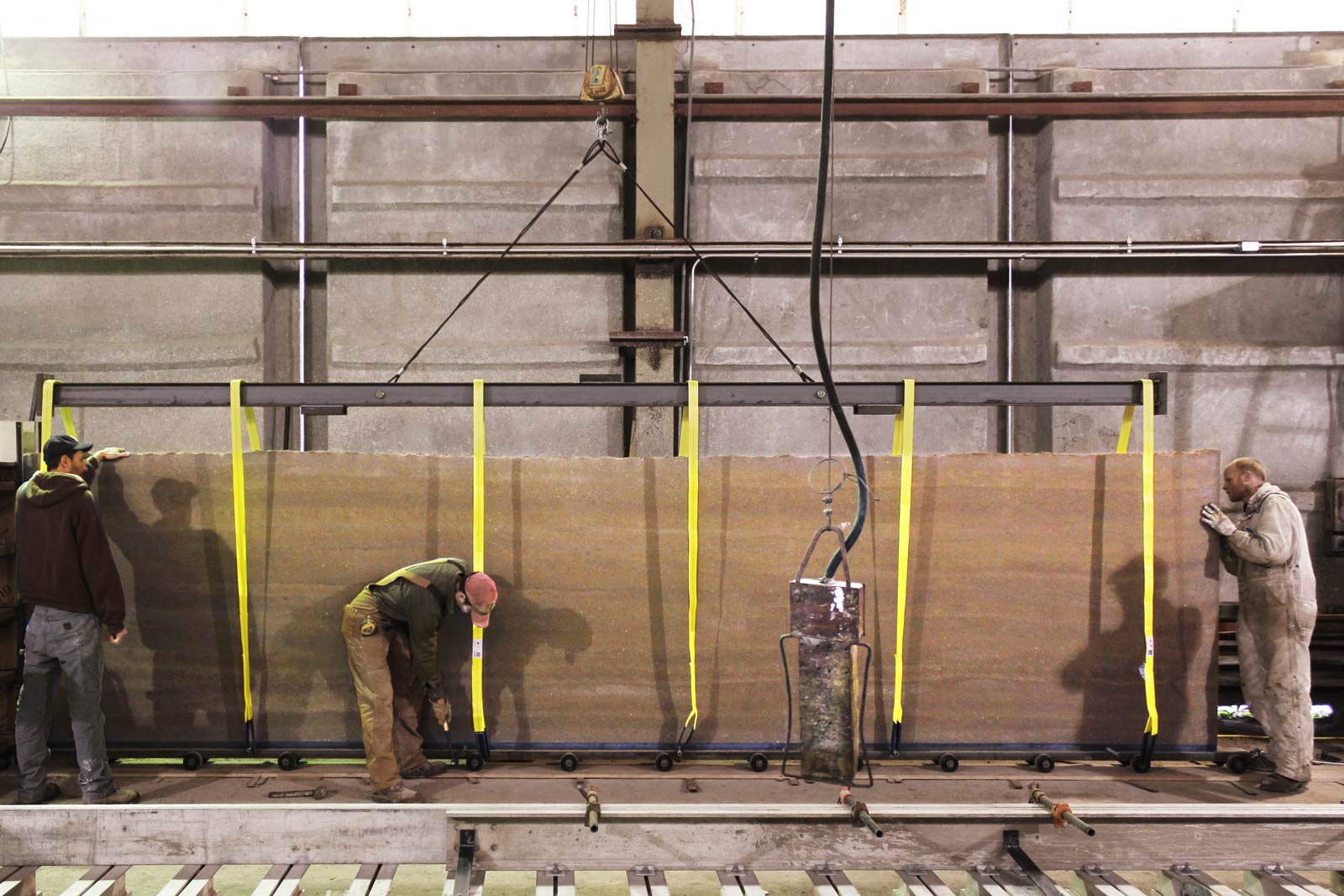

The safest way to transport and mount the big panels was to support them in a steel frame, with lifting hooks welded to the frame. Notice the subtle changes in strata and color patterns between these two panels.

The wall in the lobby for the Stadium TechCenter was going to be twenty feet tall and twenty-two feet long. We’d have to make four individual long panels, each panel five feet high and 6 inches thick. At 136 pounds per cubic foot, weight was going to be an issue. How were we going to get these long, thin panels onto a truck, drive them sixty miles, get them off the truck, and then squeeze through a front door barely wider than the panels were long? (Don’t make the mistake of thinking we could turn them sideways to get through the door because we couldn’t). Once inside the lobby we had to stack them one on top of another up to the full twenty feet, and look out! The already-installed fire sprinkler pipes were only twenty-one feet off the floor.

OK, back at the shop. We designed a steel frame made from five inch angle iron and flat bar with intermediate rebar. The idea was that we would have a rammed earth wall built within a hidden steel frame - stiff enough to transport without breaking and strong enough to mount onto the wall at the Stadium TechCenter. We welded temporary hooks onto the frame so we could lift the panels up once they were fully cured. We made one frame for each panel, and used our standard rammed earth forms to encase the frames while ramming. The forms were reusable.

Relatively straightforward so far. We had a lot of color work and small sample walls to study before we satisfied the architects on what the wall was going to look like, but once we had our formulas - there were six different mix designs - the real work of mixing and compacting could begin. It is much more complicated to create a wall of multiple colors and variable lift depth than a monochromatic wall of uniform lifts. Each mix pile was labeled and the equipment operators had written instructions on when to change colors. Khyber had his list of lift heights and where to introduce the infusion lines. And remember, each of the four panels was a different combination of color and strata to create the overall composition of the mural. This was definitely not a blow and go type of install. It’s more like painting a watercolor landscape while wearing a blindfold.

For the installation of the four big Stadium TechCenter panels, we used a long reach forklift to set the panels rather than a crane because the roof was already on the building. The forklift picked each of the five foot high panels off the truck, backed directly into the lobby with only inches to clear the door frames, executed a ninety-degree turn and placed the panels one on top of another against four steel posts where they were welded in place.

The panels within their encased steel frames cured at the shop for a month before it was time to deliver them to job site in Santa Clara. We wanted to be confident that we could pull it off, so we went through a practice run at the shop, picking up one of the panels and placing it on top of a lower one. On the job, we had to coordinate timing and installation carefully with the project supervisor because there were dozens of other trades working there, and pretty much everybody was in each other’s space. We needed the front of the building to park our forty-foot delivery truck so we could off-load our panels and get them through the front door (which as I pointed out was only one foot wider than our panels).

We used a high reach forklift to pick each panel off the truck, back directly in through this narrow opening, rotate ninety degrees, and then slowly drive the panel forward until the backside made contact with the steel columns that would support the group of four stacked panels. The forklift held each panel in place while the flat bar was permanently welded to the columns. The assembly was a nail biter, but I’m happy to say it went off without a hitch. Dare I say, “almost like we planned it.”

Thirty thousand pounds of stratified rammed earth mounted on the wall in Santa Clara is a good feeling for us. Massive rammed earth walls, built the old way, take up prime space in the building and valuable time in the construction scheduling. Simply speaking, there are many projects where classic rammed earth is just not practical. Slimming down has opened a lot of new doors. Whether it’s an art piece on the wall or a rainscreen cladding, rammed earth has a bright and bold new future.

Twenty feet tall and six inches thick, the “mural” of stratified rammed earth mirrors the geological diversity of California’s Coast Mountain Range, and celebrates the diversity of California’s multi-ethnicity. Image © Michael David Rose